SUCCESS STORIES

1. wire rope lubrication case history

Industry: Port and Marine

Wire rope was prematurely changed because of lubricant used.

Wire rope was prematurely changed because of lubricant used.

we proposed lubricating two new wire ropes, one with the old lubricant and one with Chesterton 715 Spraflex.

we proposed lubricating two new wire ropes, one with the old lubricant and one with Chesterton 715 Spraflex.

Then testing with non-destructive test device TCK to check for internal number of flaws and its magnitude.

after 2 months the old lubricant wire rope needed to be re-lubricated, and the device detected 54 flaws with magnitude of 2.69% of the maximum flaw.

While the wire rope lubricated with Chesterton 715 Spraflex, the device only detected 15 minor flaws with magnitude of 0.99% for the maximum flaw.

this shows great success and saving of extending the wire rope lifetime and decreasing the amount of lubricant used.

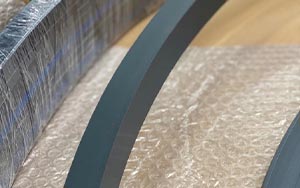

Chesterton 715 lubricated wire rope.

2. Pulsarlube case history

Industry: Food and Beverage ( maize plant )

Mixer bearings premature failure due to high load and inconsistent re-lubrication.

Pulsarlube automatic lubrication device was installed remotely, and grease used was Chesterton 615 HTG.

Over and Under lubrication was eliminated and the good quality grease increased the bearing lifetime tremendously.

3. EPS Case history

Industry: Aluminum plant

OEM seals with time started aging and making scratches in the Ram which lead to leakage.

This Ram would be very expensive to repair or replace.

Chesterton Engineered polymer solution with 2 different materials to withstand the high pressure and seal on the existing scratches on the Ram without the need to repair or replace it.

The seals were installed successfully and operating for more than 2 years now without any problems.

4. Ready Cut Gaskets

Industry: Fertilizers

Product Line: Mechanical Packing and Gasket

Product: RCG 359

A Sudden Shutdown happened, and they must disassemble the converter for maintenance.

Accordingly, they should replace all the gaskets in the equipment which sizes can reach up to 1952 mm in diameter.

Given that the maximum sheet size is 1500mm x 15000mm, it would cause them to import the original gasket that would lead to 2-3 months shutdown.

Each day will cost 2-3 Million EGP ( $125k – $187.5 k)

After Studying the Operating conditions,

we recommended the 359 Gasket to work in this condition.

The only way to deliver such sizes in short term, was to Design and Cut SPLIT Gaskets.

With our Gasket Design Team, and the CNC in EL Panda Co. Workshop.

We Delivered the required gaskets in

5 Days!!